Fraunhofer IMWS / 2025

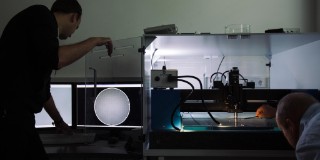

New process to enable the conversion of CO2 into sustainable basic chemicals

The sustainable production of chemical base materials using CO2 as a carbon source is the goal of the "PKat4Chem" project. The project partners involved aim at further developing the process of low-temperature plasma catalysis so that gases produced from biomass can be converted into methanol or ethylene in a single-stage process. The Fraunhofer Institute for Microstructure of Materials and Systems IMWS is contributing its expertise in analyzing the materials used. The approach promises high efficiency and flexibility.

more info